iGentoo Robotics Automation Solution – Safe Robots

- Classification:Jintu AI Intelligent Robot

- Release time:2025-12-09

- Page views:0

iGentoo Robotics Automation Solution – Safe Robots

- Classification:Jintu AI Intelligent Robot

- Release time:2025-12-09

- Page views:0

iGentoo robots can automate operations using standardized IP skills, CLM skills, and general AI skills, supplemented by expert experience or operational planning. Using the robot's task flow orchestration engine, various tasks can be quickly created and executed 24/7. After each task is completed, customizable work reports are generated as needed, improving the quality and efficiency of various tasks and enabling business innovation and digital integration.

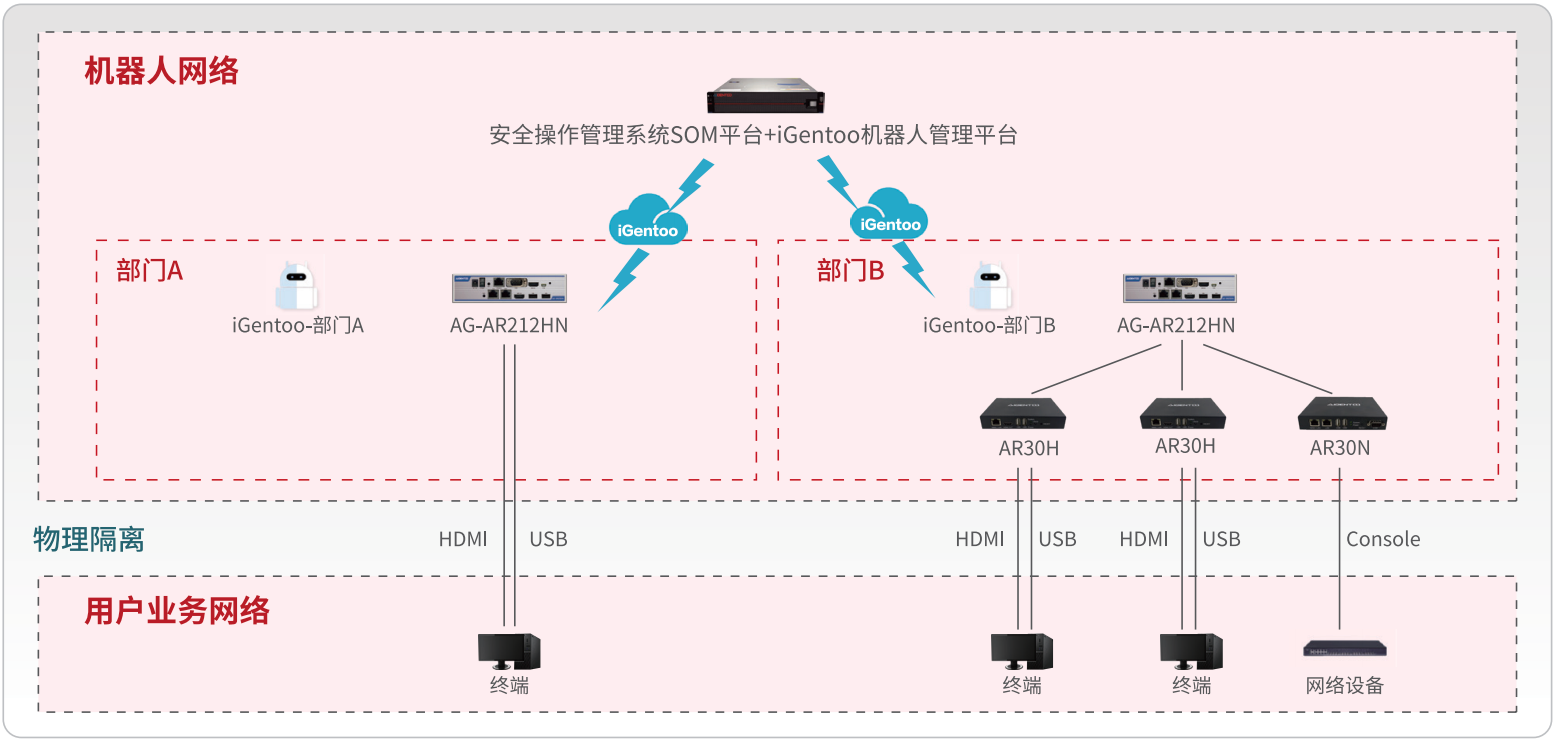

The core deployment utilizes a GPU-enabled Safety Operation Management System (SOM) platform, which also serves as the management and application platform for iGentoo robots. The number of GPUs increases with the number of robots. Each iGentoo robot is equipped with an AR212HN execution unit, which is also the interaction unit between the robot and the execution target or terminal. One execution unit can control one terminal or console device to complete the robot's operation. In addition, one execution unit can also control multiple execution targets (AR30H/AR30N), issuing operation instructions for each step of a task to the corresponding execution targets. After the execution targets control various types of terminals or console devices to complete the operation instructions, they are summarized back to the execution unit, which then sends them to the SOM platform, thereby completing a complex task across devices or networks.

Application scenarios

2. Safety Robot

Stability and security are perpetual tasks in information technology construction and management; there is no end, only an ongoing process. The iGentoo robot breaks through the limitations of working hours, and its ability to operate stably and efficiently 24/7 demonstrates unique value in the field of security assurance.

- 7*24-hour security monitoring robot: The robot "watches" various security situation platforms 24/7, promptly detects and resolves problems, responds quickly, and handles them efficiently, reducing the risk and impact of various security incidents;

- Daily safety monitoring robot: It conducts daily inspections of various relevant safety monitoring platforms, collects relevant safety alarm information, and can automatically process some events and generate robot work reports. Other specific events generate daily reports for analysis and judgment to assist in decision-making.

- Asset Security Review Robot: The robot uses technical means to detect the viability of assets and outputs a report on surviving but unrecorded assets to ensure the security of online assets;

- Security Hardening Robot: Human-machine collaboration ensures a closed loop in vulnerability management within a vulnerability remediation cycle. The robot discovers a vulnerability, notifies operations and maintenance personnel to perform patching and hardening upgrades, and the robot verifies the effectiveness, generating a vulnerability risk tracking record to ensure a closed loop in vulnerability management;

- Account Security Management Bot: The bot automatically manages VPN accounts, various access accounts, wireless accounts, etc. It can generate account management reports on application, activation, usage records, and account revocation to ensure access security.

- Security Equipment Software Inspection Robot: The robot checks the software versions of relevant security equipment daily to ensure that all security libraries are the latest versions. The robot can automatically upgrade and generate a daily version report of security equipment.

- Safety Equipment Inspection Robot: The robot inspects all safety equipment daily, leveraging the expertise of various safety manufacturers to maximize the value of the corresponding safety equipment;

- Heterogeneous safety equipment linkage robot: Without the need to coordinate the R&D and product interfaces of different manufacturers, the robot can quickly link different brands of safety equipment at the operational level, which is flexible and efficient.